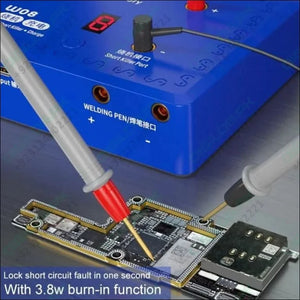

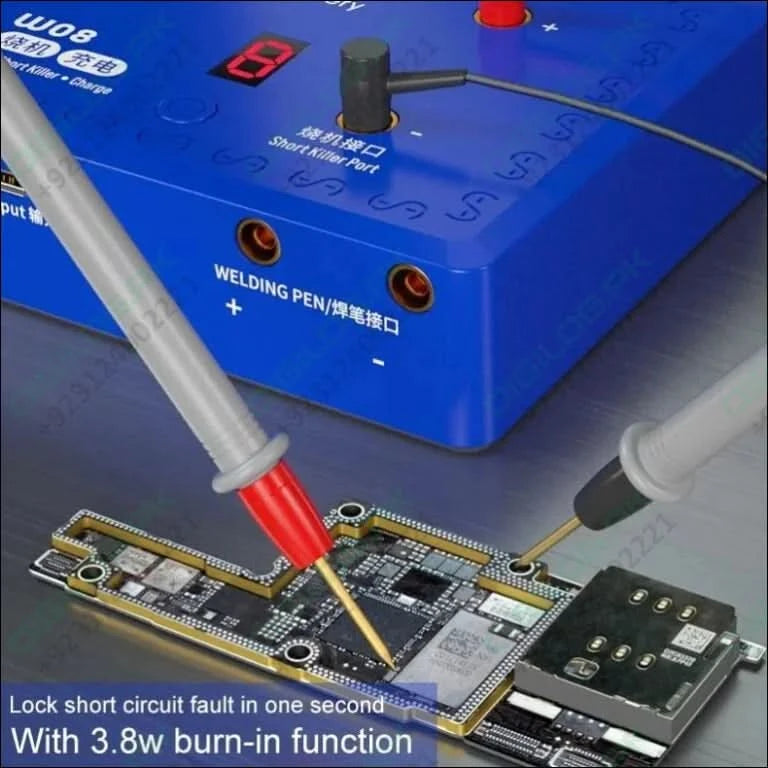

Mechanic W08 Mini Spot Welder

Guaranteed Safe Checkout

Mechanic W08 Portable Mini Battery Welder Spot Welding Machine

1. W08 Mini Precision Spot Welding Machine Suitable for precision welding of mobile phone electronic components, battery plate replacement, lithium battery nickel sheet, etc.

2. W08 portable spot welder uses a high-multiplier lithium battery as the power supply, mainly used for welding of nickel sheets of cylindrical batteries. This W08 DIY soldering machine can be used to solder the battery protection board when replacing the battery.

3. Precise voltage, meticulous pen tip, eight-speed adjustment, one machine for multiple uses.

4. Suitable for precision welding of mobile phone electronic components, battery plate replacement, lithium battery nickel sheets, etc.

5. Comply with mobile phone industry-standard operating voltage to avoid breakdown of battery cells.

6. Break the precision of the traditional soldering pen, the pen tip is as fine as 0.

Product type: Welding Equipment

A mini spot welder is a compact and portable welding machine designed for making quick and precise spot welds, often used in automotive and small-scale manufacturing applications. Spot welding is a process where two or more metal surfaces are joined together by applying heat and pressure at specific points, creating a weld spot. This type of welding is commonly used in the assembly of sheet metal parts and thin metal components.

-

Compact Size: Mini spot welders are generally smaller and more portable than traditional welding machines, making them suitable for small workshops or DIY enthusiasts with limited space.

-

Spot Welding Capability: The primary function of the device would be to perform spot welding. It may have adjustable settings for controlling the welding time, current, and pressure to achieve consistent and reliable welds.

-

Electrode Design: The spot welder would likely come with a pair of electrodes that are used to clamp the workpieces together and conduct the welding current through the contact points. These electrodes could be replaceable and might come in various shapes and sizes to accommodate different types of workpieces.

-

Control Panel: There might be a control panel with buttons or knobs to adjust the welding parameters such as time, current, and possibly welding mode (e.g., single spot, continuous welding).

-

Safety Features: Mini spot welders might include safety features such as overcurrent protection, thermal overload protection, and possibly even a safety interlock to prevent accidental operation.

-

Display: Some models might include a digital display to show the current settings, welding time, and other relevant information.

-

Power Source: The spot welder might be powered by standard electrical outlets and could have a power rating suitable for the intended welding applications.

-

Cooling System: Since spot welding generates heat, there might be a built-in cooling system to prevent the device from overheating during prolonged use.

-

Accessories: The package could include additional accessories such as extra electrodes, welding tips, and possibly a user manual or guide.

Customer questions & answers

Ask a question

No questions yet. Be the first to ask!